Published on: Monday, 01 July 2024 ● 5 Min Read

Aircraft construction figures are on the way up again. But the demands for efficiency in production still remain high. This has given rise to challenges for machining companies in particular. High machining volumes must be achieved quickly, reliably and economically. The machining tool specialists at Walter have developed a range of high-performance tools specifically for aluminium machining, with which the possibilities of modern machine tools can be optimally utilised.

The aviation industry and aircraft construction have been through a difficult few years. The worldwide travel restrictions due to the COVID-19 pandemic have not only led to yawning emptiness at airports, but also to massive slumps in production. The market has now recovered and passenger numbers are rising again.

Modernisation push for aircraft fleets is offering opportunities For aircraft construction, of course, this is good news. The profound transformation that was already underway in the sector before COVID-19 is gathering dynamic momentum with changing passenger demands, energy costs and CO₂ emissions. Airlines are adapting their existing fleets to these new demands, for example by modifying the cabin area. Many fleets also need to be modernised.

But even if the order situation in aircraft construction is looking up, the production environment and conditions remain challenging for the industry. Economic and political crises around the world are placing entirely new demands on the resilience of our own supply chains. Two other major players – China and India – have firmly established themselves on the market. Production and value chains are shifting. So the pressure on efficiency and cost-efficiency of processes remains high.

High-performance machining systems are making new demands

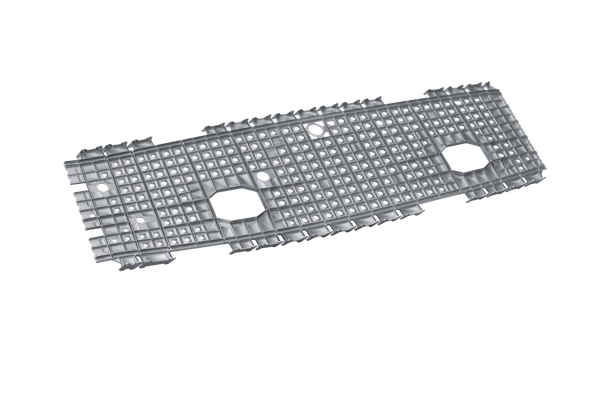

Particularly in the complex and demanding field of aluminium machining, process managers are therefore looking for ways to reduce costs per part and increase output. Components such as frames and wing ribs are often milled out of the solid material. Components several metres long also require large and cost-intensive machines. In order to be able to produce the necessary high machining volumes, mechanical engineers are developing machining centres with increasingly powerful spindles. Today, values above 80 kW are standard – the latest generation of machines has a spindle output of around 130 kW. However, pure power alone has not yet made any machining process fundamentally more efficient. The machining tool that is used is an important factor in offering the component the machine performance that is theoretically possible in reality, too. Only with the appropriate tool and a well set-up process can the potential of a modern high-performance machining system with spindle outputs of up to 130 kW actually be used economically and reliably.

Optimal tool solutions for high machining volumes With a sophisticated range of high-performance tools, machining solutions provider Walter has been helping customers in the aircraft construction industry to achieve their efficiency goals for years. The company invests significantly in further developing its existing machining solutions and designing new ones. This is well illustrated by the 'new sales ratio'. At Walter, the proportion of tools that have been on the market for less than five years is currently over 25 per cent. The MD265 Supreme and MC268 Advance solid carbide milling cutters have been on the market since October 2022. They were specially developed for high machining volumes when machining ISO N materials such as aluminium alloys, which are frequently machined in aircraft construction.

The developers have placed particular emphasis here on optimising the micro-geometry. The special "V-shaped centre cutting edge" is typical of both milling cutters – a Walter development that is so far unique on the market. The new cutting edge enables reliable ramping with less thermal input into the workpiece. This prevents structural changes in the material that can occur when using conventional milling tools. This is because temperatures of up to 480 °C can be achieved here selectively at high machining rates under minimum quantity lubrication. This can affect the electrical conductivity of the material and lead to it being disqualified during quality testing. With the new centre geometry, the temperature remains below 140 °C. In addition, the cutting edges, Kordel or RAPAX profiles and flutes are finely polished so that hardly any machined material adheres to them. The special micro-geometry enables smooth cutting, resulting in high process reliability. Users can also work with a reduced cutting force – which saves on spindle output and maximises the efficiency of the output used.

With its Kordel profile, the MC268 Advance is designed as a universally applicable roughing tool. The MD265 Supreme with RAPAX profile is designed for the maximum metal removal rate. Its NHC coating is designed for a metal removal rate of up to 9.2 litres per minute in Al7075 in 24/7 operation. This metal removal rate is achieved with a tool with a diameter of 25 mm at 33,000 revolutions per minute and a feed per tooth of 0.15 mm, as well as a depth of cut and width of cut of 25 mm each. The required spindle output is about 120 kW. The maximum value of current machine tools is optimally utilised.

30 per cent productivity increase in aluminium: The Walter DC166 solid carbide drill The DC166 Supreme solid carbide drills have been on the market since April 2023. Designed for mass producers who need to drill many identical holes in an aluminium alloy workpiece, the drills make productivity increases of up to 30 per cent possible. Due to the optimised cooling towards the centre and the strong thinner web as well as the polished flutes, a significantly higher feed rate can be operated with the DC166 drill. In some cases, the machining time can thereby be halved. In addition, tool life is increased due to the reduced built-up edge. This standard tool with through coolant is specially designed for minimum quantity lubrication (MQL) and cooling with emulsion.

No comments posted

© 2019 KIVAA Group | All right reserved. www.theindustrial.in

Leave a reply: